As a competent service partner for balancing systems we are pleased to be available for you from consulting and sales to start-up, maintenance, repair and rebuilding of HAIMER-balancing machines. As an expert for balancing technology we offer an instruction & training to handle the balancing machine correctly. Furthermore, you can acquire original manufacturer parts of our spare parts storage. We are pleased to offer you a balancing service of different parts (item/tool) with a detailed balancing protocol. If you have a common cutting point (HST, TS, BT, Capto) or an individual order, all services are executed in our company.

Our Balancing Technology Services

Balancing technology services - flexible, fast and competent

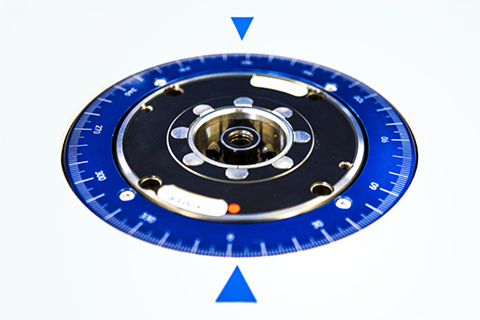

Fine balancing - balanced tools are profitable

They minimises vibrations, preserves the cutting edge of a tool and reaches brilliant surfaces.

With SWT Services you will avoid damages of mandrel and storage. As well as you use full speed and cutting capacity of your tool machine!

We balance for you:

- Tool holder

- Grinding wheels

- Cranks

- Rotors

- Pump impellers

- Pulleys

- Flanges

- Tools

- and much more

Start-up

Our worldwide on-site service helps to ensure that your production can start up quickly.

Your advantage:

Benefit from our qualified technicians, from installation to commissioning – and this with a trouble-free production process.

Our services:

- Assembly and start-up of your balancing machine

- Maintenance of your machine on the basis

of a detailed checklist - Testing of all technical functions

- Registration of all important data – customised

- Training of all machine operators

- Answer open questions

Contract balancing

As a competent service partner, we can balance workpieces or tools of any kind up to 30 kg, 440 mm in diameter and 700 mm in height at a fixed price. We can also provide you a measurement report of unbalanced tools.

All services – whether standard interfaces (HSK, SK, BT, Capto) of any size or customized special fixtures, which are designed and manufactured according to your wishes – are carried out at SWT.

An ideal service if you want to experience the advantages of finely balanced tools in practice.

Maintenance

SWT Services is a worldwide active expert for cross-manufacturer clamping-, flexo printing and balancing technology service.

With the systematical maintenance of the balancing machines thanks of our balancing technician experts you will guarantee a correct function of your balancing machine as well as you can exclude measurement errors.

All this is available at a fair all-inclusive price.

The SWT maintenance fixed price for balancing machines includes the following services:

- Registration of actual condition

- Complete cleaning

- Control of function

- Spindle check

- Position zero angle

- Examination of the safety arrangements

- Software control

- Analysis of diagnostic report

- Calibration

- Inspection protocol/testing label

- Spare- and wear parts service

- Additional costs

Overhauling

You can get a fast and professional support of SWT Services in every special case. Short distances for suitable spare parts are guaranteed. Because of this you can continue easily with the manufacturing after a machine breakdown.

Your advantage:

At SWT Services you get always the service which is required for your individual request. If you have an error or machine breakdown you can profit of our qualified service technicans on-site or in our company. Our highly experienced technicans get back to you immediately and resolve possible problems fast and competent.

Our services:

- Checking of your balancing machine (target-actual-difference)

- Overhauling of your tools on site or at our location

- Spare parts supply

- Exchange of damaged components

- Function testing of all parts according to the checklist

- Training of all machine operators

Balancing machine - modernization / retrofit

New operating elements or the latest software make handling your balancing machine faster and easier.

Your advantage:

With comparatively little financial outlay, you can achieve significantly greater ease of operation. In this way, you can bring your balancing machine up to date sustainably and cost-effectively.

Balancing - training & instruction

Our practical and individual training will teach your employees to work efficient with balancing machines.

Your advantage:

Our qualified engineers provide the knowledge of the operating of your balancing machine at your location. This prevent an incorrect application and guarantee a production process without problems. Because of this you will extend the service life of your clamping tool and increase the technical knowledge of your employees.

Our services:

- Training of all machine operators

- Practical instruction on-site

- Information exchange

- Answer to open questions

Balancing technology - spare parts & accessories

Our worldwide on-site service is also responsible for the operation of your balancing machine.

Your advantage:

You can benefit from a fast supply of spare parts which enable lesser machine breakdowns. We offer you all spare parts from one source, in best quality and availability. The suitable accessory is essential for your balancing machine and it can extends service life.

Our services:

- Support with the identification of the parts

- Stock keeping of original parts

- Short delivery times, parts are handed over to the carrier on the day of the order

- 12 months warranty on all spare parts